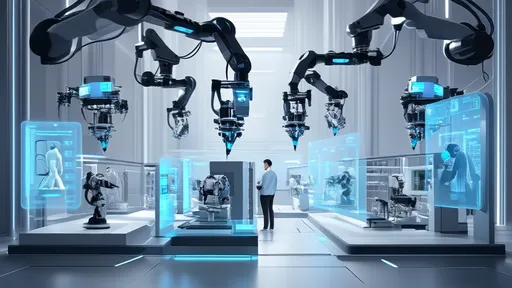

The air at the CHIC exhibition hall hummed with a different kind of energy this year. Beyond the vibrant textiles and bustling fashion shows, a quiet revolution was unfolding. The convergence of Artificial Intelligence and 3D printing is no longer a futuristic concept whispered about in R&D labs; it has materialized onto the production floor, presenting a new paradigm for intelligent manufacturing solutions that are as elegant as they are efficient.

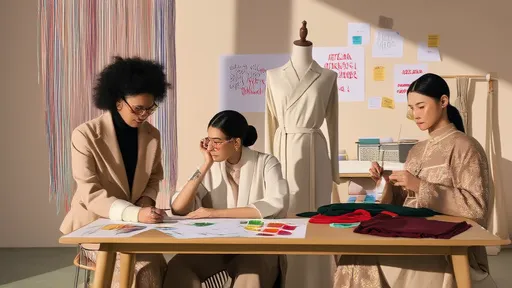

The most striking aspect of this integration is the profound shift from mass production to mass personalization. For decades, the apparel and consumer goods industries have been dominated by the economics of scale, producing vast quantities of identical items. Now, AI-driven design algorithms are working in concert with advanced 3D printers to dismantle this model. At one booth, a system captured a customer's precise body measurements through a simple scan. This data was instantly fed into an AI platform that not only adjusted a base garment design to fit perfectly but also suggested stylistic modifications based on the user's indicated preferences. Minutes later, a nearby industrial 3D printer began constructing a unique, custom-fitted piece of fashion-forward eyewear, its lattice structure optimized for both weight and strength by the very same AI. This is not mere customization; it is the on-demand creation of truly personal products.

Behind the scenes, the intelligence goes much deeper. The role of AI extends far beyond the initial design phase into the very heart of the production process. Generative design software, a subset of AI, is being used to create components that are impossible for a human engineer to conceive. Designers simply input goals and constraints—such as required strength, weight, material usage, and maximum size—and the AI iterates through thousands of potential designs, learning from each iteration. The result is often an organic, intricate structure that uses the minimum amount of material to achieve maximum performance, perfectly suited for the additive, layer-by-layer nature of 3D printing. This synergy is leading to parts that are lighter, stronger, and more resource-efficient than anything achievable through traditional subtractive manufacturing.

Furthermore, AI is acting as the vigilant guardian of print quality and production efficiency. High-resolution cameras mounted on 3D printers continuously monitor the printing process. The video feed is analyzed in real-time by computer vision algorithms trained to detect anomalies—a slight warping of material, a potential nozzle clog, or a layer adhesion issue. Upon detecting a flaw, the system can automatically pause the print, alert an operator, or in some advanced setups, even initiate a self-correction routine. This predictive maintenance drastically reduces waste from failed prints and ensures consistent, high-quality output. This level of automated quality control transforms 3D printing from a sometimes-unpredictable craft into a reliable, industrial-grade manufacturing process.

The impact on the supply chain is equally transformative. The traditional model of manufacturing products in low-cost regions and shipping them across the globe is being challenged. With intelligent 3D production solutions, the concept of the digital inventory emerges. Instead of warehousing physical goods, companies can store digital design files locally. When an order is placed, the nearest distributed manufacturing hub—which could be a dedicated facility or even a network of local print shops—can produce the item on-demand. AI optimizes this network, routing orders to the most geographically and capacity-appropriate printer to minimize shipping time and cost. This not only slashes logistics expenses and carbon footprints but also empowers businesses to respond with unprecedented speed to market trends and regional demands.

Material science is another frontier being expanded by this powerful duo. The range of materials compatible with 3D printing has exploded, from polymers and metals to ceramics and advanced composites. AI is crucial in navigating this complexity. Machine learning models can predict how new material formulations will behave during the printing process and in the final product, accelerating development cycles. Moreover, AI-powered systems can optimize print parameters—such as temperature, speed, and layer height—specifically for each material and each unique geometry, ensuring optimal results every time. This intelligence is making advanced materials more accessible and reliable for end-use production, not just prototyping.

Perhaps the most profound long-term implication is the emergence of a self-optimizing production ecosystem. As these intelligent 3D printing systems operate, they generate vast amounts of data. AI algorithms analyze this data to find patterns and correlations invisible to the human eye. They can identify ways to reduce energy consumption, suggest design tweaks that will improve printability, and forecast machine maintenance needs before a breakdown occurs. This continuous feedback loop means the manufacturing system is constantly learning and improving upon itself, driving efficiency gains that compound over time. It is a step towards the realization of the autonomous factory, where human intervention is focused on high-level strategy and creativity, while AI manages the complexities of execution.

Of course, this technological leap is not without its challenges. The initial investment in advanced AI software and industrial-grade 3D printers remains significant. There is a growing need for a skilled workforce capable of operating and maintaining these sophisticated systems—a blend of data science, engineering, and traditional manufacturing knowledge. Intellectual property concerns around digital design files also require new legal and security frameworks. However, the demonstrations at CHIC made it clear that the industry is actively addressing these hurdles, driven by the immense potential on offer.

In conclusion, the CHIC exhibition served as a powerful testament to a new industrial reality. The integration of Artificial Intelligence and 3D printing is moving beyond prototyping to create genuinely intelligent production solutions. This synergy is enabling hyper-personalization, creating smarter and more efficient designs, ensuring impeccable quality, and building more resilient, localized supply chains. We are witnessing the dawn of an era where manufacturing is not just automated, but cognitive—a system that can see, learn, and adapt. The factories of the future, as glimpsed at CHIC, will be less about rows of identical machines and more about interconnected, intelligent cells capable of producing exactly what is needed, when and where it is needed, with remarkable efficiency and minimal waste. The future of production is not just printed; it is thought into existence.

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025