The digital fabric of our future is being woven not on traditional looms, but within the intricate codes of the metaverse. Here, self-expression through fashion is unbounded by physics, yet paradoxically, its creation and disposal are beginning to cast a long, tangible shadow on our physical environment. A quiet revolution, however, is brewing at this intersection, promising to redefine sustainability for both our digital and physical selves. The convergence of 3D printing and fully biodegradable materials is poised to transform metaverse apparel from a fleeting digital asset into a catalyst for a circular, conscious future.

The allure of metaverse fashion is undeniable. It offers limitless creativity, where garments can defy gravity, shimmer with impossible light, and change form at the wearer's whim. This burgeoning economy, with its digital-only NFTs and virtual runways, was initially celebrated as the ultimate sustainable alternative—no water consumption, no textile waste, no carbon-heavy supply chains. But this perspective is proving to be shortsighted. The environmental cost has simply been displaced. The energy-intensive servers powering blockchain transactions for NFT ownership and the vast data centers required to render these complex virtual worlds contribute significantly to a digital carbon footprint. Furthermore, the prevailing model of digital fast fashion—cheap, disposable virtual items with little lasting value—mirrors the worst habits of its physical counterpart, promoting a culture of waste, albeit in a server farm rather than a landfill.

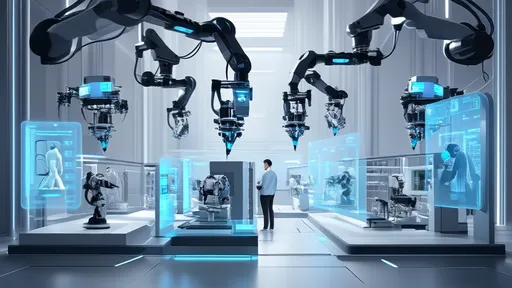

This is where the paradigm must shift. The true potential of metaverse fashion lies not in its isolation from the physical world, but in its ability to inspire and directly influence it. The vision is a new ecosystem where a digital garment is not an endpoint, but a genesis. Imagine designing a stunning, intricate gown for your avatar. Using advanced 3D modeling software, you perfect every fold, texture, and dynamic element. This digital file then becomes the blueprint for a physical manifestation. Instead of being sent to a conventional factory, the design is fed into a sophisticated 3D printer. But the magic isn't just in the printer; it's in the material it uses.

The feedstock for this new era of fabrication is a suite of advanced, fully biodegradable materials. We are moving beyond early bioplastics to intelligent polymers derived from sources like algae, mycelium (the root structure of mushrooms), and fermented plant sugars. These are not mere alternatives; they are upgrades. Researchers are developing materials that can be programmed with specific lifespans. A festival outfit could be designed to compost in a matter of weeks after the event, while a more durable jacket could last for years before harmlessly returning to the earth. These materials can be engineered to possess a wide range of textures—from silk-like smoothness to leather-like toughness—all while being printed with complex, lattice-based structures that are both lightweight and strong, impossible to achieve with traditional cut-and-sew methods.

The synergy between digital design and 3D printing is profound. 3D printing, or additive manufacturing, is inherently less wasteful than subtractive methods. It builds objects layer by layer, using only the material necessary, leaving no scrap fabric on the cutting room floor. This process allows for hyper-personalization. A digital design can be instantly adjusted to the exact measurements of an individual's body scan, creating a perfect, bespoke fit without the need for multiple samples or size inventories. This on-demand production model dismantles the traditional fashion cycle, eliminating overproduction, which is one of the industry's greatest sins. Garments are created only when there is a confirmed desire for them, slashing waste at its source.

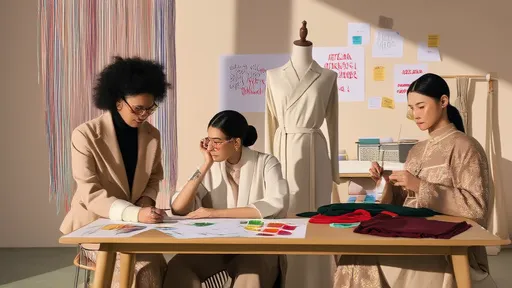

This approach fosters a deeper, more meaningful connection between the consumer and their clothing. When you are involved in the digital creation of a garment and witness its physical birth through a unique, localised printing process, the item ceases to be a disposable commodity. It becomes a story, a piece of functional art with a known origin and a predetermined, gentle end-of-life. This emotional investment is the antithesis of fast fashion. It encourages a wardrobe of cherished, well-made pieces rather than a closet overflowing with transient trends. Brands can build new business models around this, selling digital designs that owners can have printed as needed, or offering subscription services for temporary, compostable fashion.

The implications for sustainability are monumental. We can envision a future with zero-waste fashion lifecycles. A garment, after its useful life, is not thrown away. Instead, it is composted, with its nutrients returning to the soil to grow the very feedstocks for the next generation of clothing. This creates a beautiful, closed-loop system that mimics natural cycles. Water pollution from dyeing processes can be drastically reduced as 3D printing allows for colour to be integrated directly into the material matrix. The carbon footprint of global shipping is minimized as production can be decentralized, with local micro-factories (or even home printers) producing goods from digital files sent across the internet.

Of course, this future is not without its challenges. The technology for high-speed, high-resolution 3D printing with advanced biomaterials is still scaling. The cost needs to become more accessible to achieve widespread adoption. We will need to develop robust composting infrastructure capable of handling these new materials. Perhaps the greatest hurdle is cultural: shifting consumer mindsets from valuing quantity and immediacy to valuing quality, personalization, and environmental responsibility. This requires a re-education about what clothing represents and what it truly costs our planet.

Nevertheless, the trajectory is clear. The metaverse, often criticized as an escape from reality, has the potential to become a powerful design lab for a better physical world. By marrying the boundless creativity of digital fashion with the tangible innovation of 3D printing and biodegradable materials, we are not just creating clothes for avatars. We are prototyping a sustainable future for humanity. This is not merely about wearing a digital skin; it is about weaving a new ethical fabric for the entire industry, one where the clothes we wear in any realm are a testament to both our creativity and our care for the world we all share.

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025

By /Sep 23, 2025